Crafting Legacy:

Dave’s Shadowboxes for Honoring Service

Dave, a retired police officer turned skilled woodworker, has found a new way to honor the service and dedication of his fellow officers. Drawing from his years of experience in law enforcement and his passion for woodworking, Dave now creates custom shadowboxes—beautiful displays that preserve the badges, IDs, and honors of retired officers. These pieces are more than just woodworking projects; they’re heartfelt tributes to years of commitment and sacrifice.

Step 1: Cutting the Frame with Precision

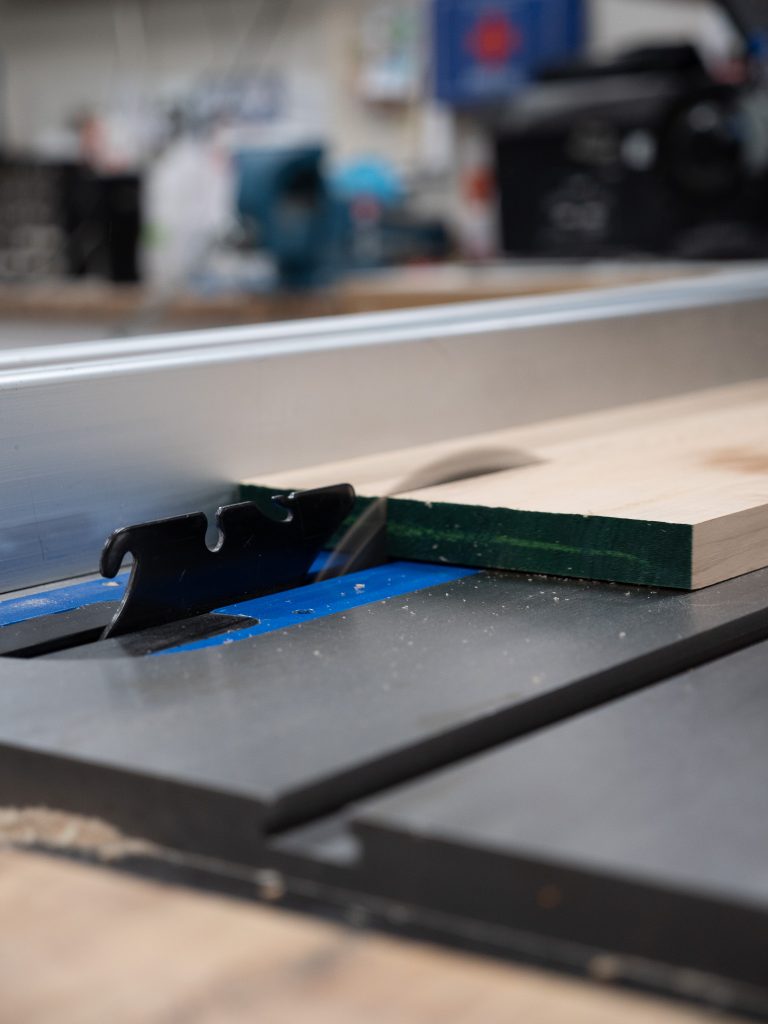

Dave starts each shadowbox by selecting premium maple hardwood for its durability and classic appeal. To ensure every cut is perfect, he turns to his Delta 36-725T2 Table Saw, adjusting the rip fence to cut the frame pieces to the exact width. The powerful motor and precision of the table saw allow Dave to create flawless edges, setting the foundation for the project.

Once the frame pieces are ripped to size, Dave moves to his Delta Cruzer Miter Saw to cut the lengths and miter the ends at precise angles. The Cruzer’s Shadowline Technology ensures each cut is exact, providing the perfect fit for a squared-up frame. With clean, accurate cuts, the frame begins to take shape, reflecting the meticulous attention to detail that goes into every shadowbox.

Step 2: Dado Cuts for Plexiglass and Backboard

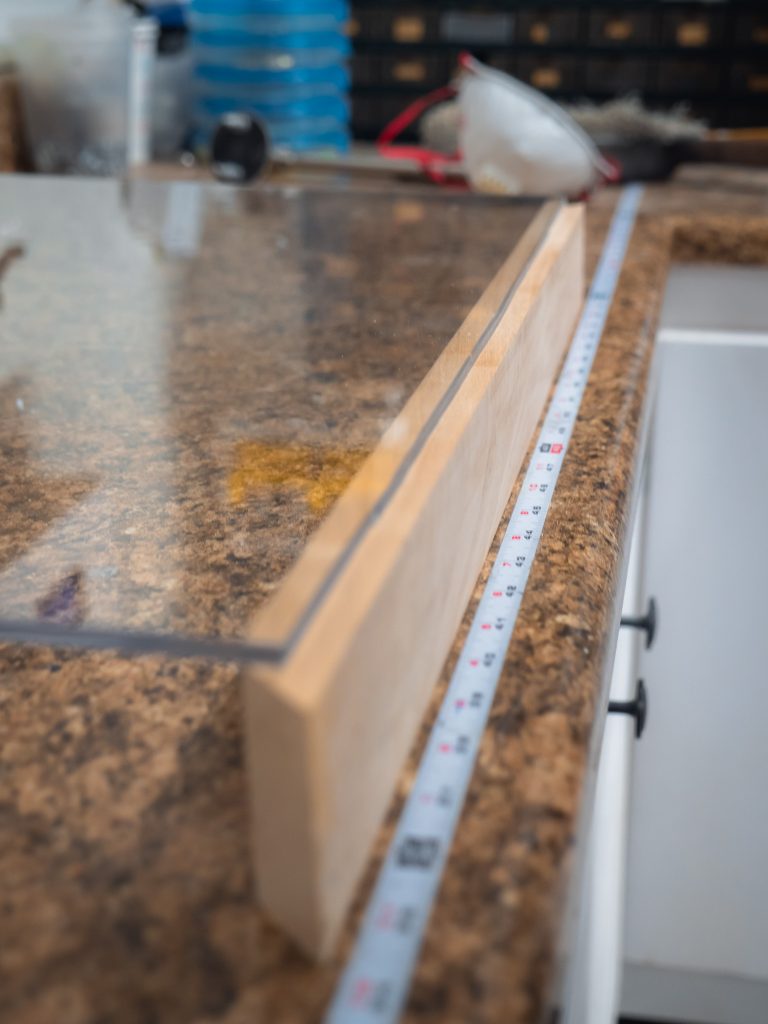

With the frame pieces cut and fitted, it’s time to create slots for the plexiglass and backboard. Dave returns to his Delta 36-725T2 Table Saw to carefully cut grooves into the inner edges of the frame. These slots are essential for holding the plexiglass in place while ensuring the backboard fits snugly.

Each dado is precisely measured and tested to guarantee a perfect fit. Dave dry-fits the pieces to ensure everything aligns properly before moving on to the next step. The precision of the Delta table saw simplifies this critical phase, allowing Dave to focus on the craftsmanship of his work.

Step 3: Sanding, Routing, and Staining

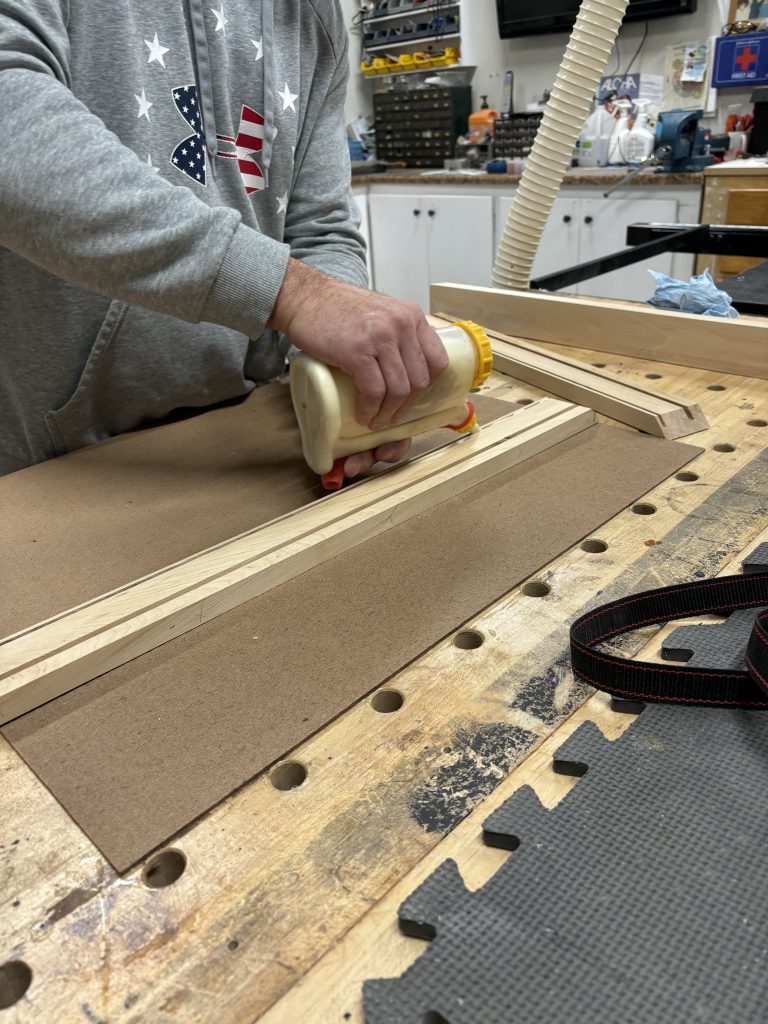

Once the frame is fully assembled, Dave sands the wood to a smooth finish, removing any rough edges or imperfections. Using a router, he adds a subtle decorative profile to the edges of the frame, giving the shadowbox a polished and professional look.

Next comes the staining process. Dave carefully selects a stain color to enhance the natural beauty of the maple, often choosing shades that complement the contents of the shadowbox. The stain not only highlights the wood grain but also protects the frame, ensuring it will last for years to come.

Step 4: Assembling the Shadowbox

With the frame complete, Dave carefully installs the plexiglass, backboard, and mounting hardware for the shadowbox contents. Each piece is assembled with precision and care, ensuring the final product is as durable as it is beautiful. The shadowbox is now ready to hold the cherished badges, IDs, and honors that symbolize a lifetime of service.

Honoring Service Through Craftsmanship

Dave’s shadowboxes are more than just woodworking projects—they’re deeply personal tributes to the men and women who dedicate their lives to protecting others. Using his Delta tools, Dave combines precision, power, and craftsmanship to create pieces that preserve and celebrate these legacies.

Whether it’s the smooth cuts of the Delta 36-725T2 Table Saw or the accuracy of the Delta Cruzer Miter Saw, the tools Dave relies on play a vital role in bringing his vision to life. Each shadowbox tells a story, honoring the past while showcasing the skill and artistry of a woodworker who understands the value of service and tradition.